Roll Forming Machines for Metal Decking

1. General Description of Detal Deck Roll Forming Machine

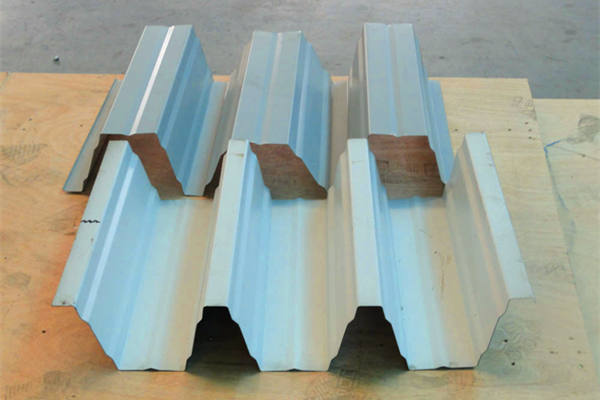

This Roll Former produce galvanised steel floor decks use in the construction of composite floor slabs.

The machine is controlled by PLC, automatic working. It can automatically record the production quantity, automatically measure the length. It has Alarm Display and Emergency Stop function. All the machine working actions can be controlled by control panel.

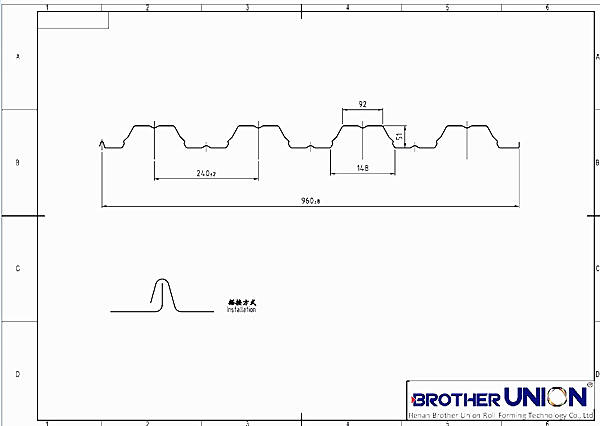

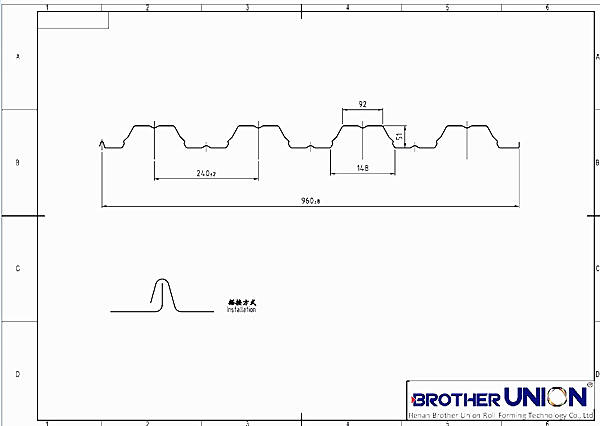

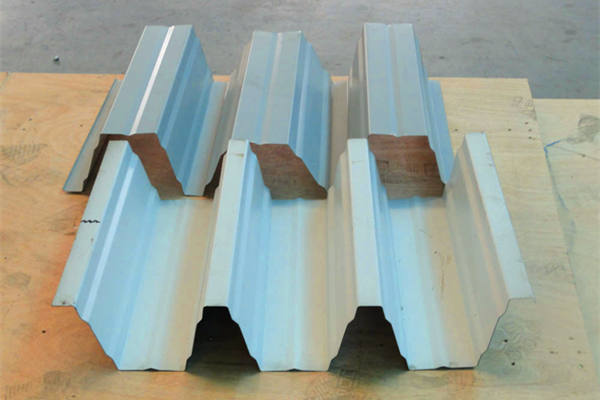

2. Floor Deck Profile Drawing

3. Raw Material of Floor Deck

| Material | Thickness | Width | I.D. | Max. O.D. | Yield strength | Max. coil weight |

| Galvanized Steel Coil | 0.8-1.2 mm | 1250mm | Ф508 mm | Ф1200 mm | ≤300 Mpa | 5 T |

4. Main Parameters of Floor Deck Roll Forming Line

| Work Temperature | -10℃~35℃ |

| Voltage | 380V±10%,50 HZ,3P (or customized) |

| Air Pressure | 0.6~1.2 Mpa |

| Total Power | ≈20KW |

| Production Capacity | about 0-25 m/min(Not include shearing time) |

| Dimension (L*W*H) | L≈ 30 m, W≈ 3m, H≈ 1.8m |

| Shipping Container | 3 (pre-estimated) |

5. Workflow of Floor Deck Roll Forming

Uncoiling → Roll Forming →Cuting →Floor Deck Stacking

6. Devices in Floor Deck Roll Forming Line

| No. | Component | Quantity | Remark |

| 1 | Uncoiler &Coil Car | 1 Set |

|

| 2 | Roll Former | 1 Set |

|

| 3 | Roller Dies | 1 Set |

|

| 4 | Cut-off Device | 1 Set |

|

| 5 | Automatic Stacker | 1 Set | Optional |

| 6 | Hydraulic System | 1 Set |

|

| 7 | Electrical System | 1 Set |

|

6.1 Uncoiler & Coil Car

Automatic Uncoiler

Structure:

Cantilever structure,Hydraulic expanding,

with press arm and brake device,

automatic rotation. welded structures.

Max Loading Capacity: 5T

Motor power: about 4KW

Coil car

Structure:

Use hydraulic cylinder to drive the car up and down.

The movement of the car is driven by motor.

Max Loading Capacity: 8T

Motor power: about 2.2 KW

6.2 Roll Former

Structure & Function:

independent column wall

Sprocket chain drive

Shaft material is 40Cr with quenching treatment, HRC45.

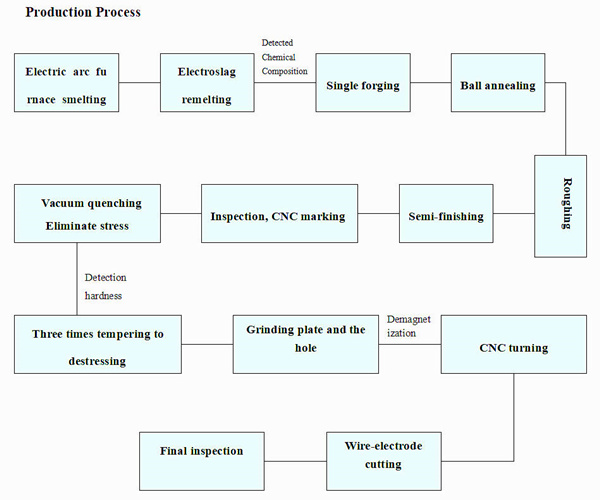

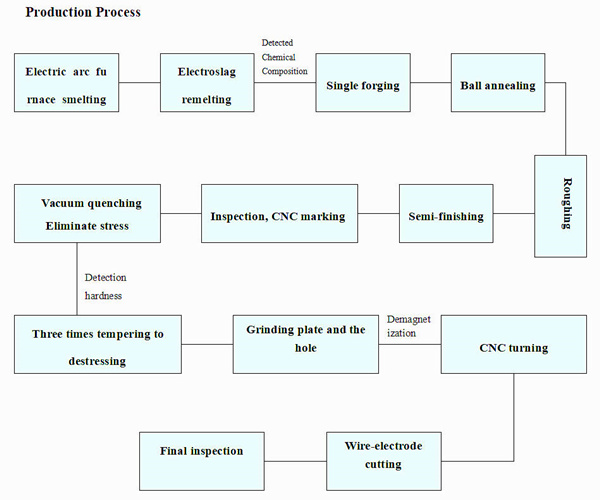

6.3 Roller Die of Roll Former

Production Process of Roll Dies.

6.4 Cut-off in Roll Forming Line

Cut-off Die is made by Cr12MoV forged

Application: To cut off the product in length.

Structure: The shearing machine adopts the motor(Or hydraulic) to drive the

cutting knife motion and complete the shearing function.