General Description of Storage Racking Profiles

In a warehouse racking or an industrial system, the most important parts are uprights, beams, decking plates (decking wire) diagonal bracings, and horizontal bracings.

Generally, the storage racking uprights are cold-roll-formed hollow profiles with holes, and the actual load capacity is improved through the multi-fold section. They are one of the most complex components in the racking system. The uprights' quality, such as strength, hole accuracy, directly affect the overall applications and stability of the steel rackings.

Because of the tremendous advantages, such as multiply the storage capacity of the warehouse, increase the logistics chain efficiency. The modern logistic racking market boosted a lot. Brother Union Machinery has been providing roll forming solutions for a variety of warehouse racking manufacturers. Especially in roll forming of the profiles of uprights, beams, and bracings.

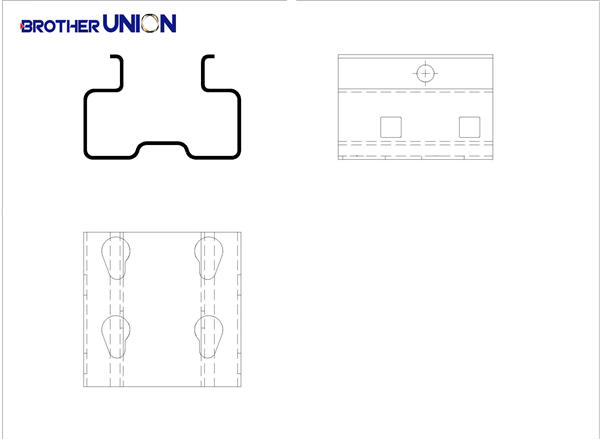

UprightsBrother Union Machinery has manufactured roll forming machines to produce racking uprights. Especially for the moden logistic racking sytem, racking uprights and beams production lines are made as to the customer's requirements. For large quantity racking profiles production, Compared to a press brake, a roll forming line by Brother Union Machinery is a better choice.

|

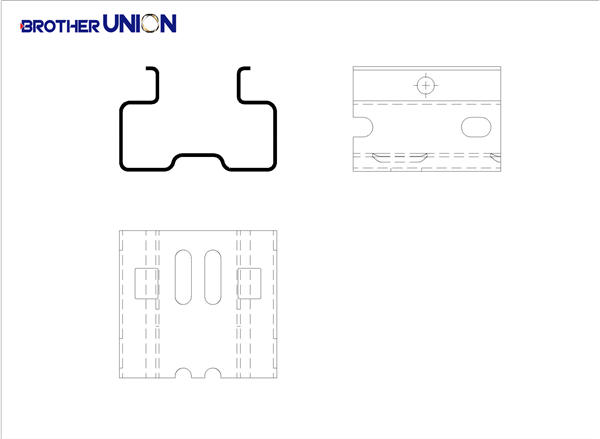

BeamsBrother Union Machinery has manufactured roll forming machines to produce racking uprights. Especially for the moden logistic racking sytem, racking uprights and beams production lines are made as to the customer's requirements. For large quantity racking profiles production, Compared to a press brake, a roll forming line by Brother Union Machinery is a better choice.

|

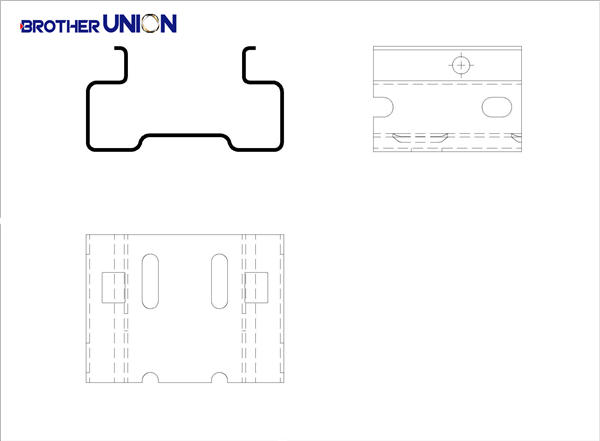

UprightsBrother Union Machinery has manufactured roll forming machines to produce racking uprights. Especially for the moden logistic racking sytem, racking uprights and beams production lines are made as to the customer's requirements. For large quantity racking profiles production, Compared to a press brake, a roll forming line by Brother Union Machinery is a better choice.

|

Brother Union Machinery is always here to serve the racking or shelving manufacturer, and we hope to receive your new roll-forming designing request with inventive racking profiles.

After all, our engineers and technicians are very skilled in custom roll forming machines.

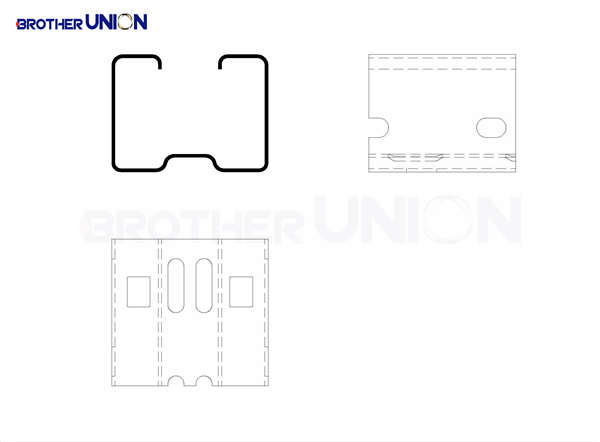

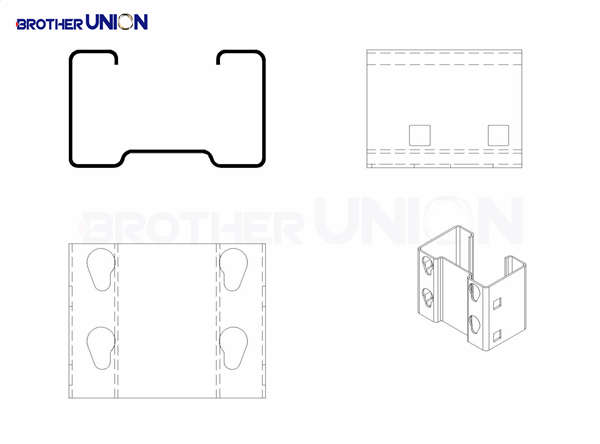

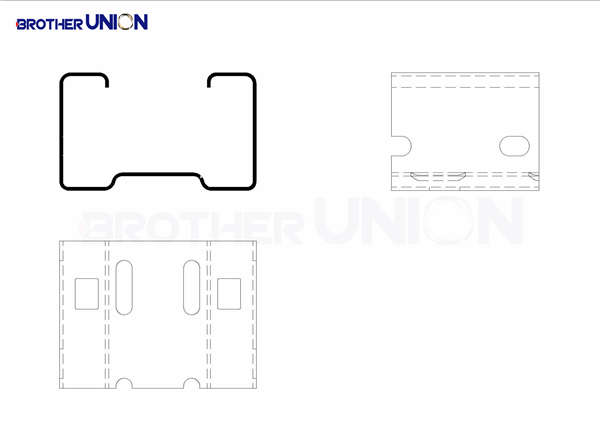

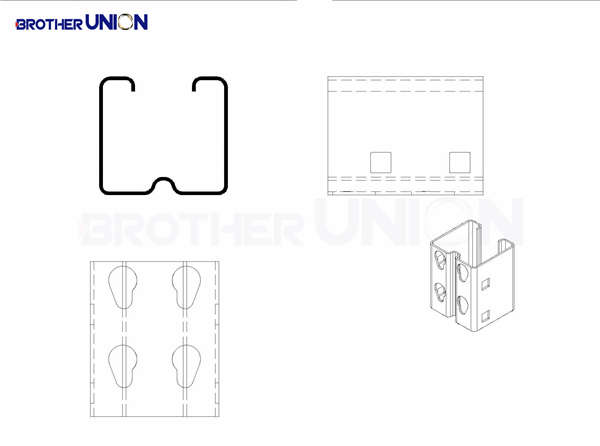

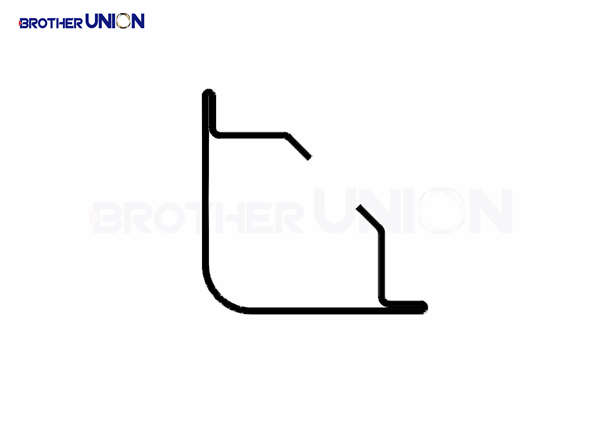

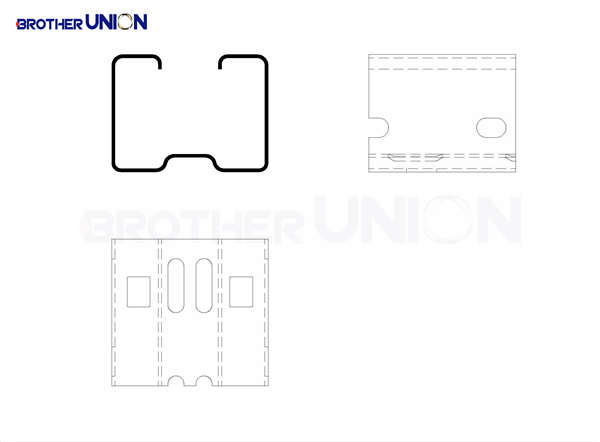

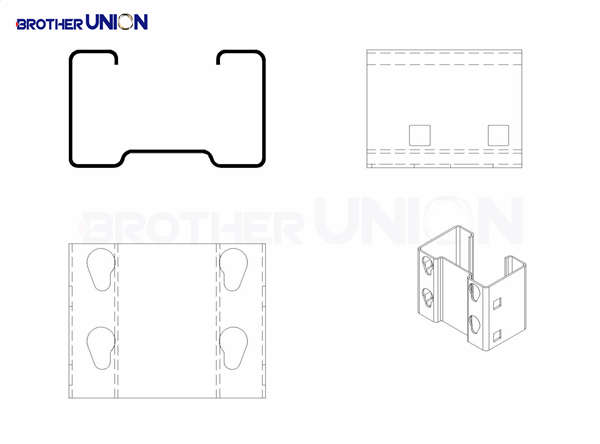

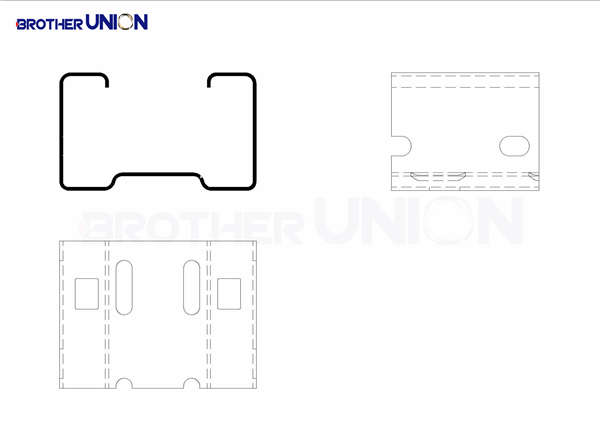

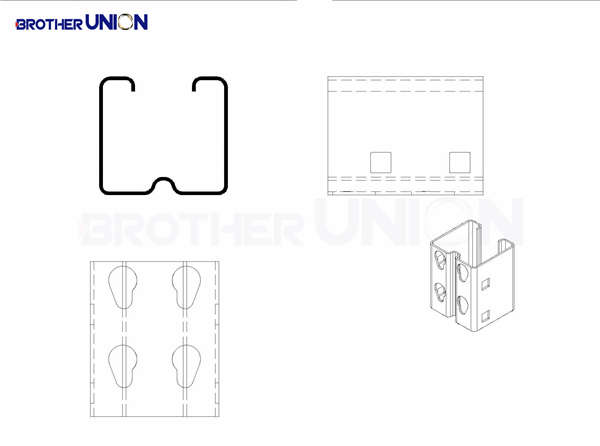

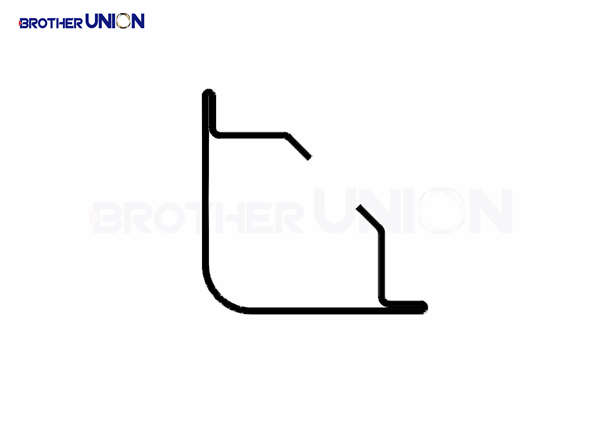

A Warehouse Racking Upright Profile

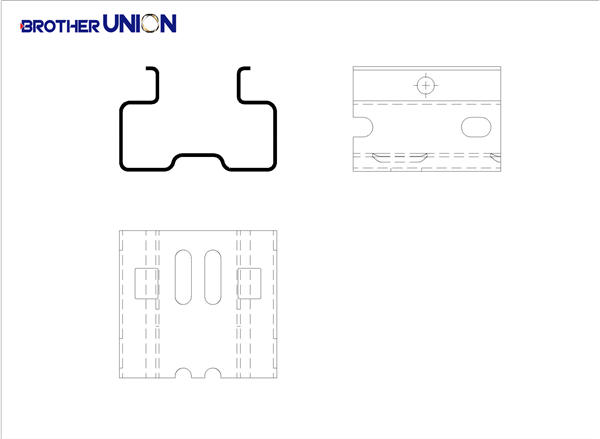

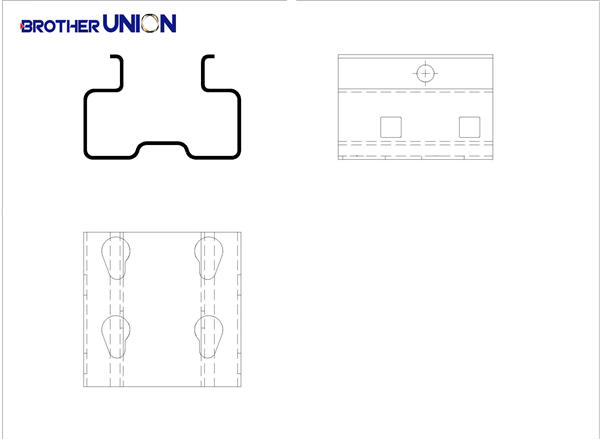

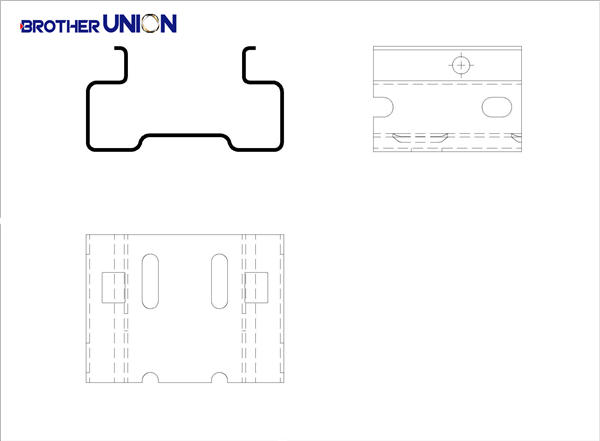

Related Metal Sheeting Profile Drawings

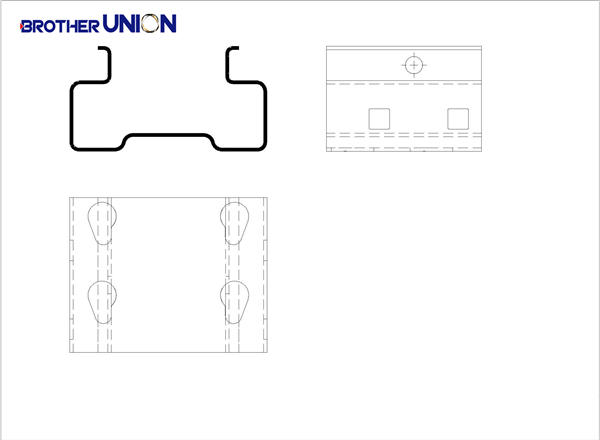

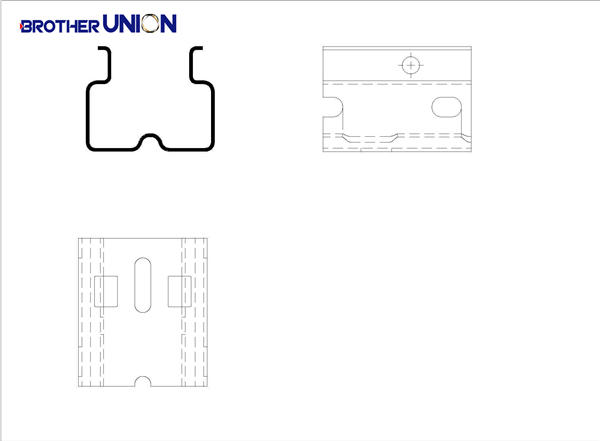

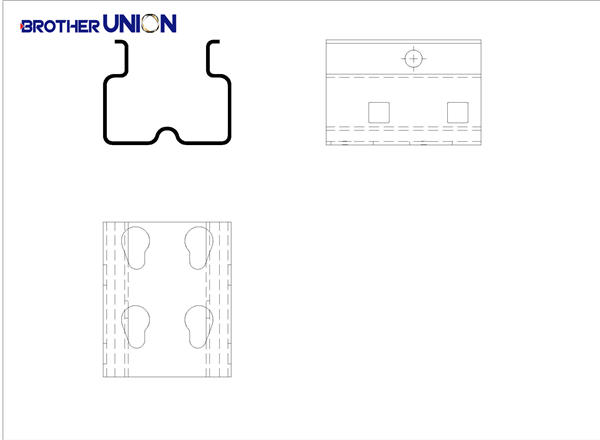

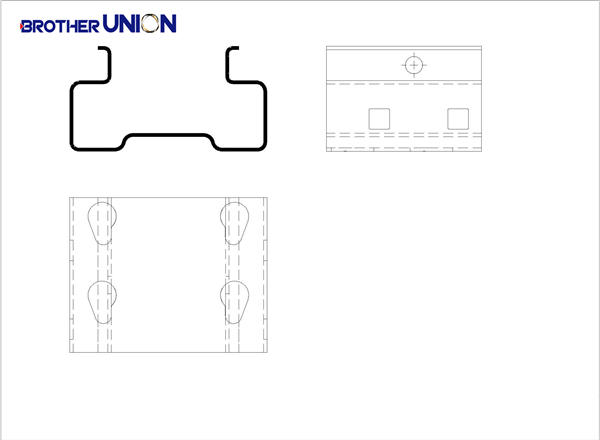

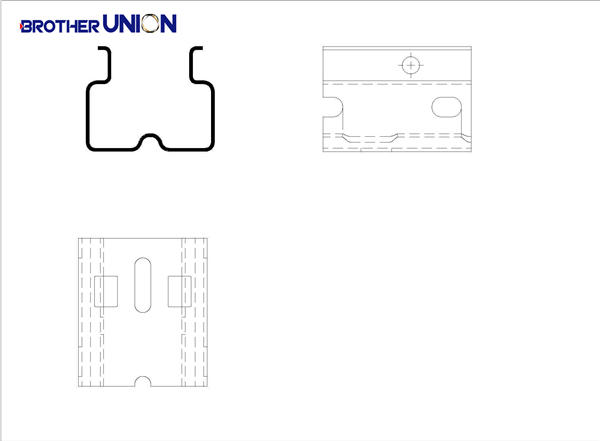

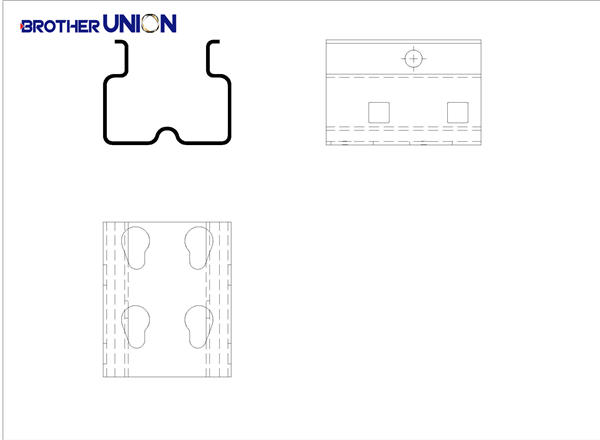

Warehouse Pallet Racking Upright Profile 01 |

|  Warehouse Pallet Racking Upright Profile 02 |

|  Warehouse Pallet Racking Upright Profile 03 |

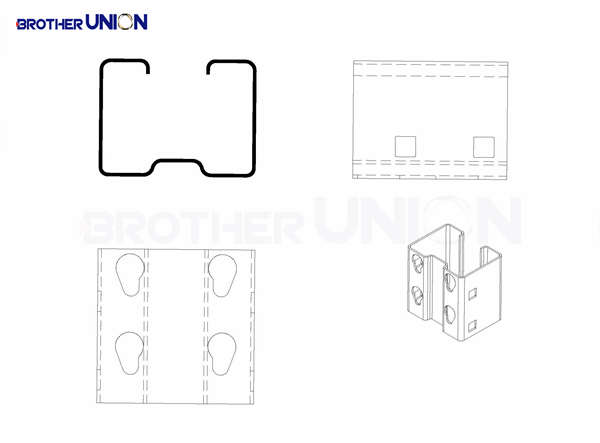

Warehouse Pallet Racking Upright Profile 04 |

|  Warehouse Pallet Racking Upright Profile 05 |

|  Warehouse Pallet Racking Upright Profile 06 |

Warehouse Shelving Upright Profile 01 |

|  Warehouse Shelving Upright Profile 02 |

|  Warehouse Shelving Upright Profile 03 |

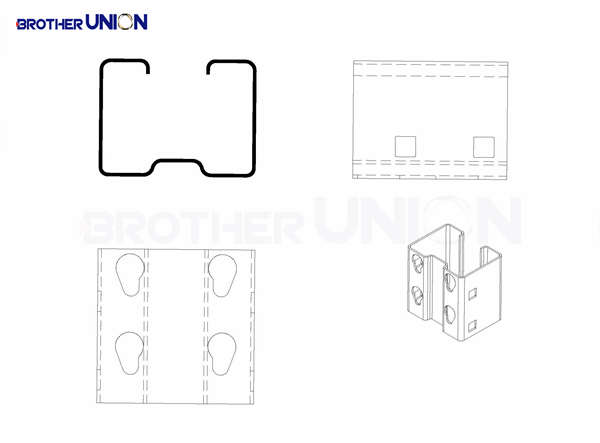

Warehouse Shelving Upright Profile 04 |

|

Warehouse Shelving Upright Profile 04 |

|

Heavy Duty Pallet Upright Profile |