Roll Forming Machine for Guard Rails

The crash barrier roll forming line produces two-beam and thrie-beam guardrails in one production line by interchangeable cassettes.

This guardrail line consists of uncoiler, leveling machine, servo-feeding machine, hydraulic press of hole-punching and pre-shearing, roll former and automatic finished products stacker with side transport conveyor.

The uncoiling machine with a pit-type coil car is fitted to large quantity production without down-time waiting for new coil loading.

The electrical control steel coil peeler help the operator to feed the thick steel coil into the production line easily.

The shear and butt welding device help operator to joint the steel coil end in shortest time, short the down-time, increase the production efficiency.

The hydraulic press punches the holes on the guardrails precisously, and a pre-shearing divide cut the profile to length accuracily for next step - roll forming.

In order to undertake the large quantity, high speed and heavy-duty roll forming production. Brother Union Machinery engineers designed stiff and steady base, precise rolls made of qualified material, strong independent stands and shafts to assure the roll forming machine a long term service.

The finished guardrails are automatically stacking into certain number and the side motorized conveyors transfer the guardrail stacks to unloading station for forklift.

Brother Union Machinery, as a professional roll forming machine and coil processing equipment manufacturer, we have been providing highway guardrail beans, post production solutions, automatic produciton line, semi-automatic line, cost-conomically line.

Customized roll forming machines and related equipment are available. Just write us an email to us, we will send the proper proposal according to your requirements.

Video of Guardrails Production Machine

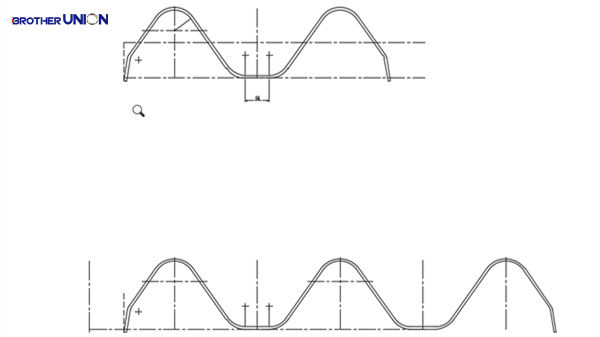

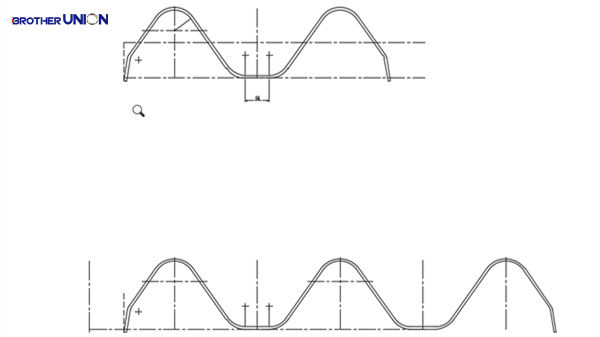

Guardrail Profile Drawing

Advantages of Brother Union Guardrail Production Machine

Sturdy machine Base and Framing, longer service life.

Quality Roller Dies made of qualifed material

Automatic control system

Finished Guardrails have accurate cut to length

Precise hole punching and accurate hole position

Free the operators' hand, save labours

Easy Installation, Easy Operation, and Easy Maintainance

High production efficiency

Cassette type roll forming for mutiple profiles of guardrails in one production line.

Cost-effective

Custom-made roll forming machines are available.

Specifications of the Raw Material for Guardrail Beams

| Specifiaction of Steel Coil for Guardrail Production (reference only) |

| Thickness(mm) | Width(mm) | Width Tolerance(mm) |

| W-Beam Guardrail | 2.5 | 486 | -0.5-0 |

| 3.2 | 485 | -0.5-0 |

| 4 | 483 | -0.5-0 |

Thrie-Beam Guardrail

| 2.5 | 754 | -0.5-0 |

| 3.2 | 753 | -0.5-0 |

| 4 | 750 | -0.5-0 |