General Description of Hollow Metal Frame Roll Forming

Hollow metal door frames are widely used in residential, commercial, and industrial buildings. Especially the places where door operating conditions are relatively bad.

Modern hollow steel door frame manufacturer has been producing a variety of stunning patterns. Some wood-like decorative galvanized steel door has both beautiful appearances of natural wood and strength of steel.

Fire-rated doors and frames play a very important role in the fire resistance of a building. Steel hollow door is the wise choice for fire-proof.

A Stainless steel door frame is not only modern and shining but also stronger, longevity, and excellent fireproof.

Developing with the modern metal door manufacturing, Brother Uion Machinery has been providing steel hollow door frame roll forming solutions for a variety of metal door manufacturers.

The following door profiles have been producing by machines made by Brother Union Machinery.

Glavanized Door Frame Roll FormingBrother Union Machinery has manufactured lots of door frame making machines. Especially for the South African market, dozens of metal door frame production lines are made as to the customer's requirements. These door frames are made of mild steel or galvanized steel, and after a protective paint coating, these door frames have a popular appearance and longer service time. For large quantity standard framing production, Compared to a press brake, a roll forming line by Brother Union Machinery is a better choice. |

Steel Framing with Decorative Coating Roll FormingModern hollow steel frame manufacturers produce door frames, window frames with flexible decorative coatings in numerous colors and textures. These framings are more expensive, but they are better suited for residential doors. Brother Union Machinery has produced a series of door frame roll forming lines to fit the European customer's higher requirements. Through the roll forming process, these PVC steel sheets go into wood-like door frames, which not only have the strength of steel but also have the beautiful wood-grain textures.

|

Security Door Roll FormingCompared to a bending machine, a roll former has its advantage to produce a large quantity of stadarad security door frames. These security door frames always have a higher thickness and visible line of corner connection.

|

Brother Union Machinery has been producing metal door frame production machines.

We are always here to serve a metal door manufacturer, and we hope to receive your new roll-forming designing request with inventive door frame profiles.

After all, our engineers and technicians are experts that experienced in metal door frame roll forming machines.

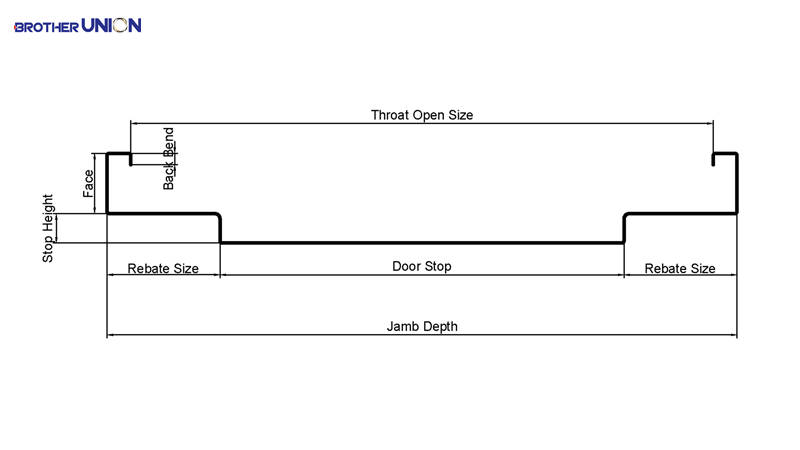

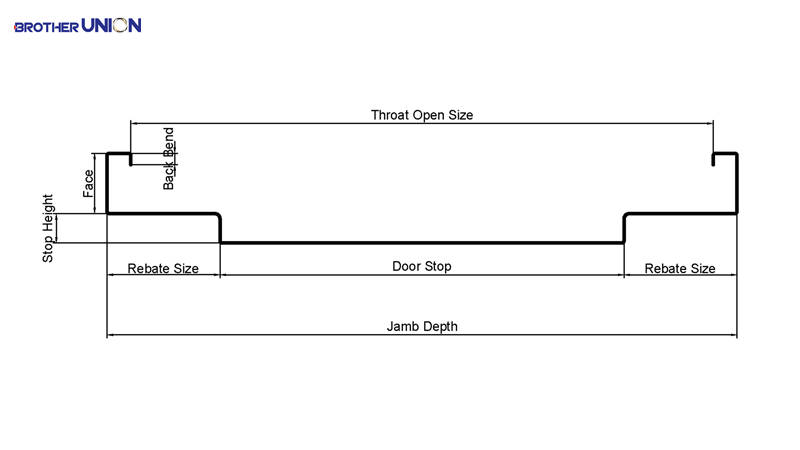

A Double-Rebate Door Frame Specification

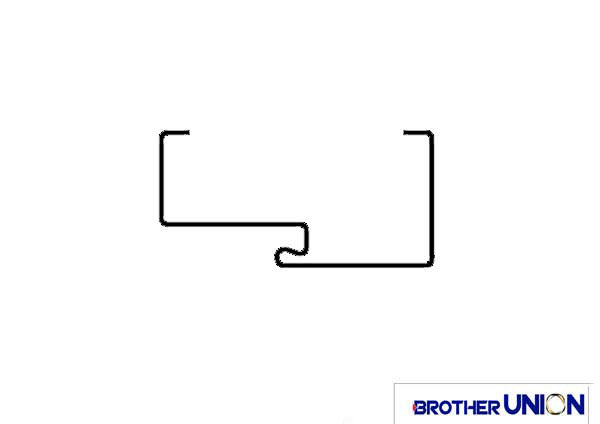

Related Metal Sheeting Profile Drawings

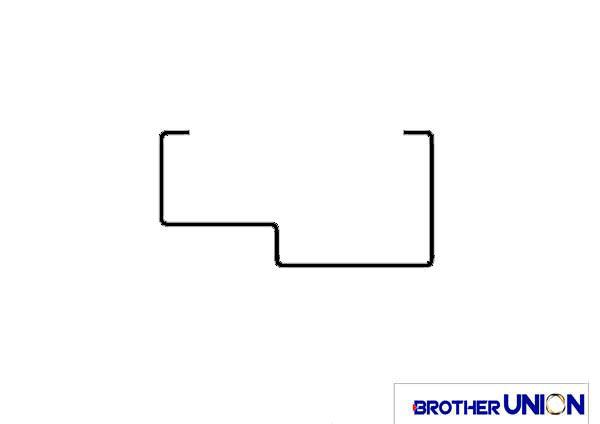

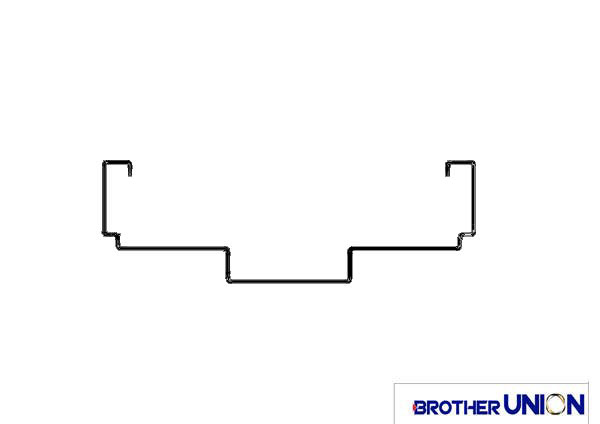

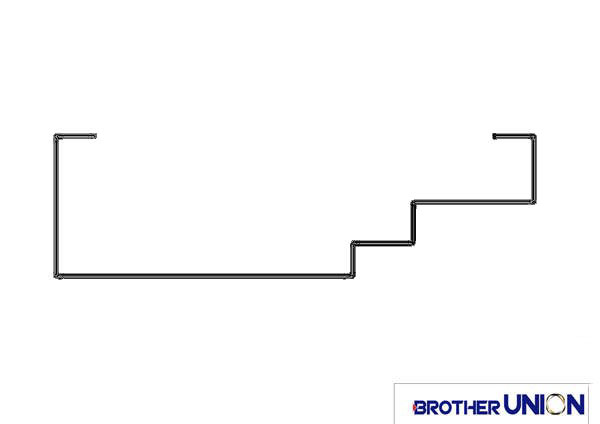

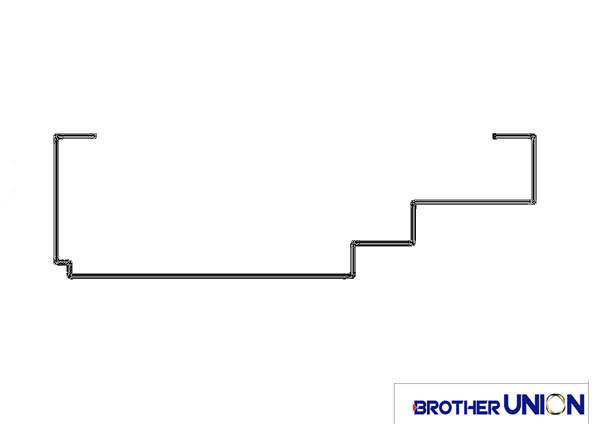

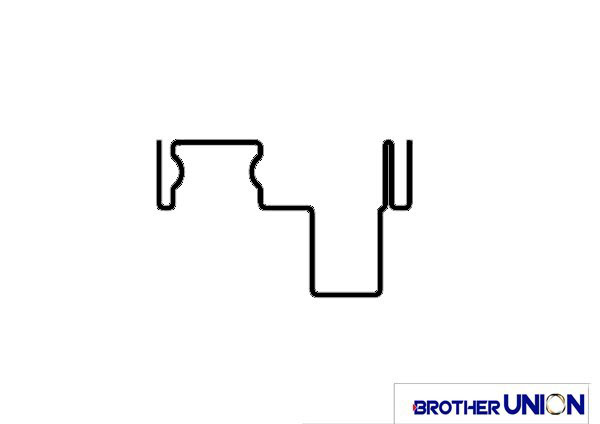

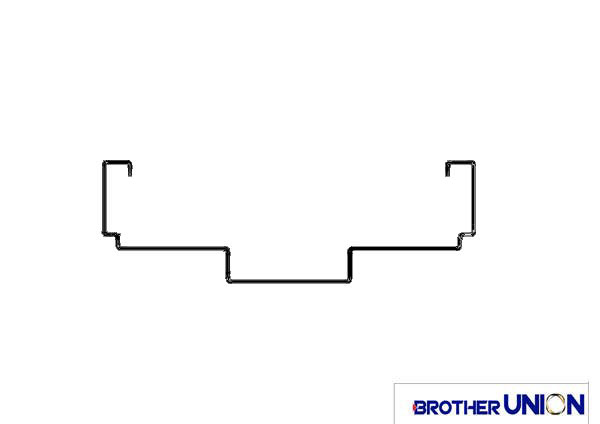

Double Rebate Door Frame with Seal Groove |

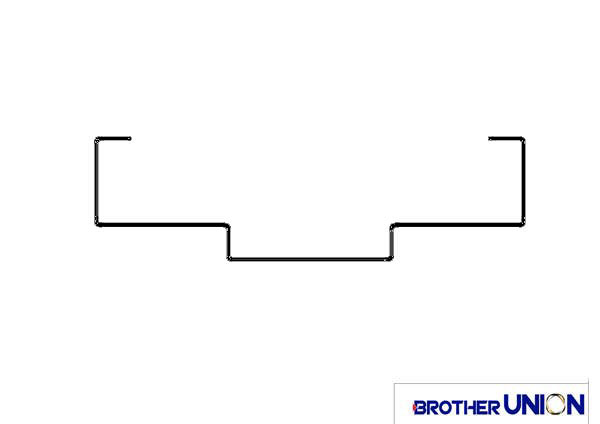

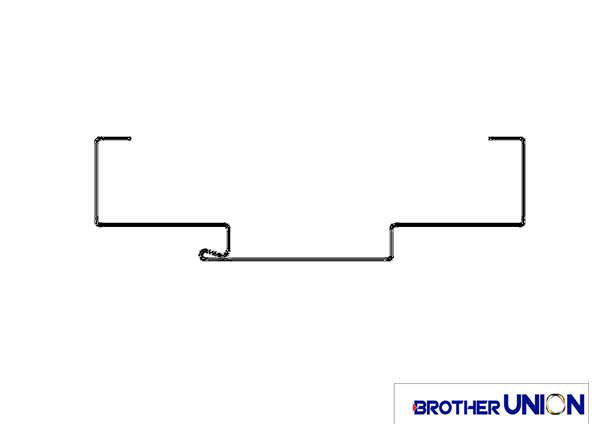

|  Double Rebate Door Frame |

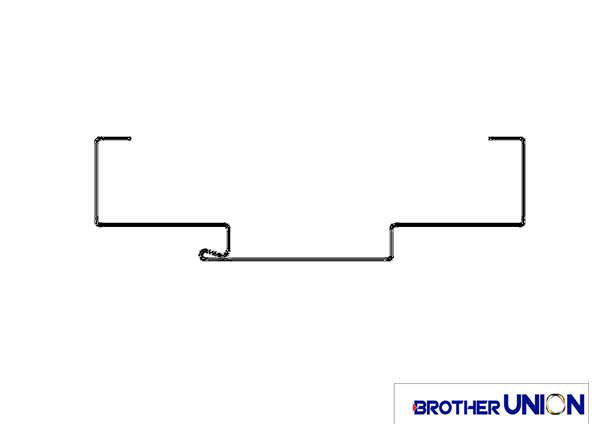

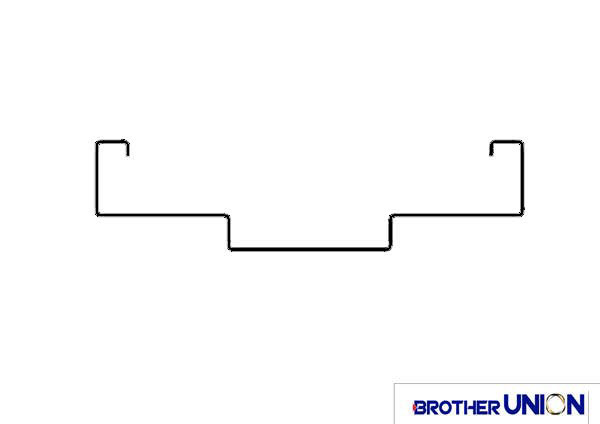

|  Double Rebate Door Frame |

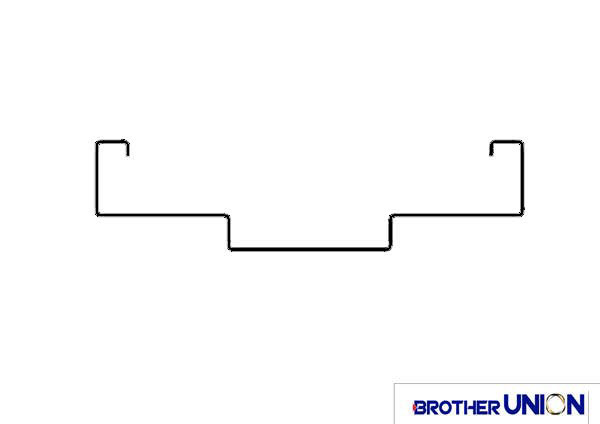

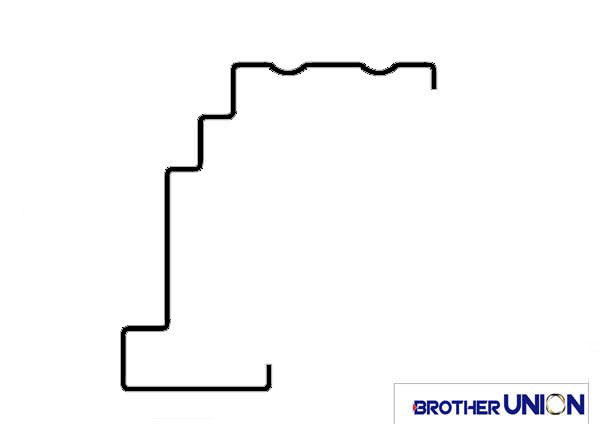

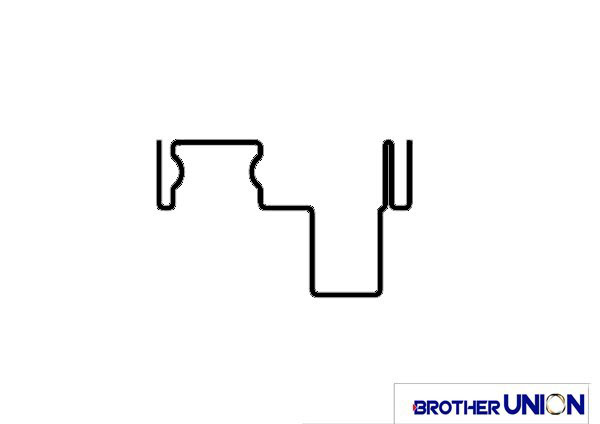

Custom Hollow Metal Frame Profile |

|

|

|

|

The advantage of steel door / window frame profile

The modulus of elasticity of steel profiles is 3 times that of aluminum alloys, and the strength of steel buildings far exceeds that of aluminum alloy profiles.

Steel profile has more span than aluminum alloy

Steel, glass, and concrete have almost the same thermal expansion coefficient, so there is no need to leave expansion joints when installing steel frame doors and windows

Steel frame door much better at fireproof, anti-theft, explosion-proof, and bulletproof.

The fireproof performance of steel frame doors and windows is far better than aluminum alloy. The melting point of steel is 1500°, and the melting point of aluminum alloy is 600°.

Steel will not melt when exposed to fire, will not release corrosive gases, and the frame will remain stable

Steel profile system can meet different grade fire proof requirements

The steel profile is strong and stable, high load, and durable, it is the ideal choice for security application.

Steel profiles are suitable for high-frequency operation, such as commercial fire-rated doors.