Square Downspout Pipe Roll Forming Machine

1. General Description of Downspout Pipe Machine

This rectangular downpipe Roll Forming Machine automatically adjusts to produce the downpipe according to client requirement. The machine is controlled by PLC, fully automatic working. It can automatically record the production quantity, automatically measure the length. It has Alarm Display and Emergency Stop function. All the machine working actions can be controlled by control panel.

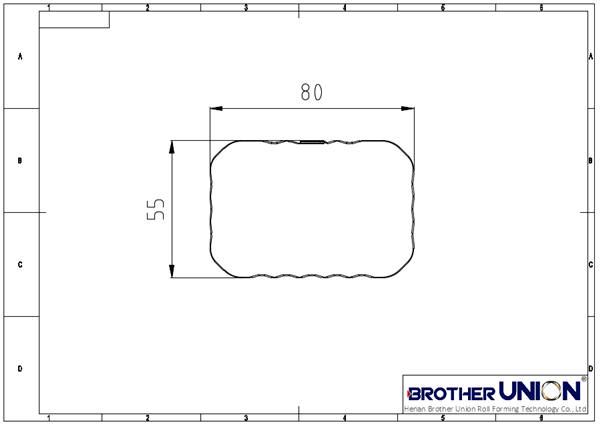

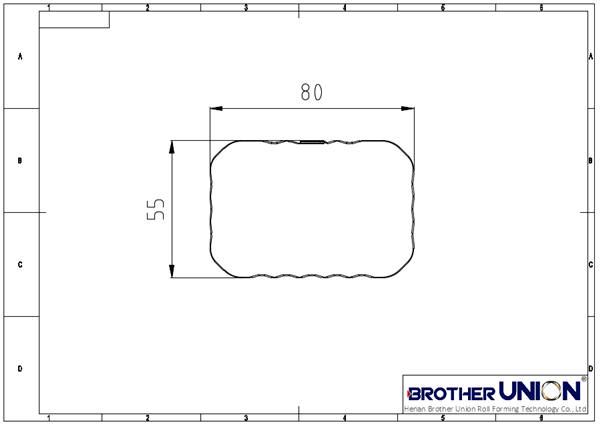

2. Downspout Profile Drawing

3. Raw Material of Downspout

| Material | Thickness | I.D. | Max. O.D. | Yield Strength | Max. Coil Weight |

Pre-coated Steel Coil

| 0.3-0.5 mm | Ф508mm | Ф1200 mm | ≤320 Mpa | 3 Tons

|

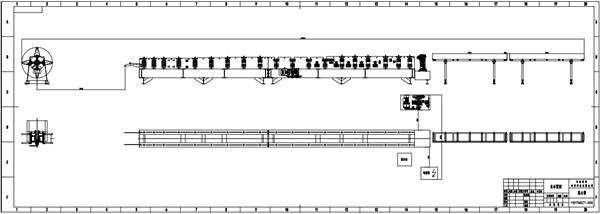

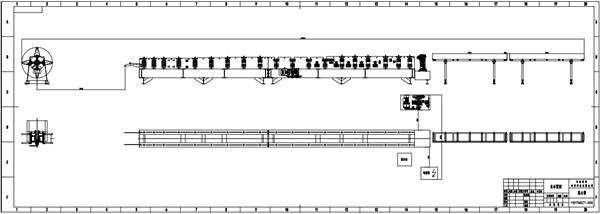

4. Main parameters of the downspout production line

| Work Temperature | -10℃~35℃ |

| Voltage | 380V±10%,50 HZ,3P |

| Air Pressure | 0.6~1.2 Mpa |

| Total Power | ≈11KW |

| Production Capacity | about 0-20 m/min(Not include shearing time) |

| Dimension (L*W*H) | L≈18 m, W≈ 2m, H≈ 1.8m |

| Shipping Container | 40GP |

5. Workflow of Downspout Machine

Decoiling →Pre-cut-off→ Roll Forming →Cuting →Stacking

6. Devices in Downspout Production Line

| No. | Item | Quantity |

| 1 | Decoiler | 1 set |

| 2 | Roll Former | 1 set |

| 3 | Roller Die | 1 set |

| 4 | Cut-off Device | 1 set |

| 5 | Hydraulic System | 1 set |

| 6 | Electrical Control System | 1 set |

| 7 | Elbow Machine | 1 set |

6.1 Decoiler in Downspout Roll Forming Machine

6.2 Roll Former in Downspout Roll Forming Machine

Independent column wall in the roll former

Driving mode: sprocket and chain.

Shaft material: 40Cr with quenching treatment, HRC45.

6.3 Roll Dies of Roll Former

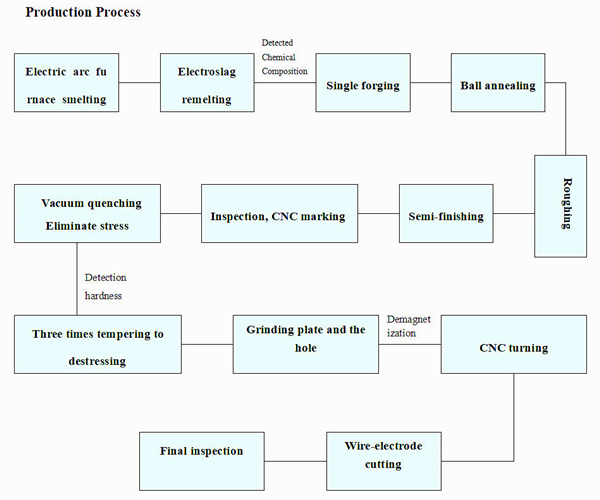

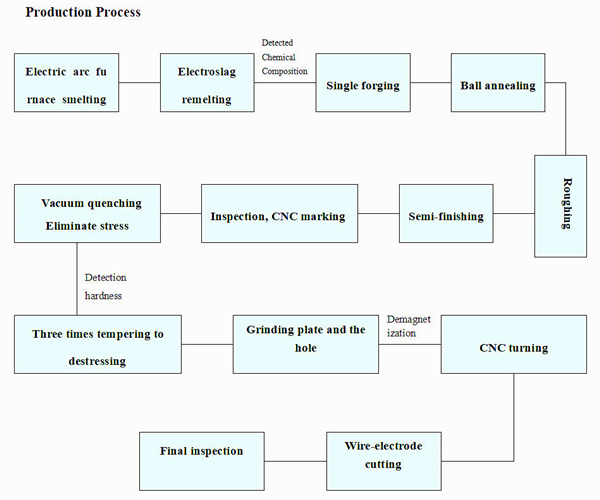

Production Process of Roller Dies of Brother Union Machinery

6.4 Cut-off

Cut-off Die Material: Cr12MoV forged;

Application: To cut off the downspout in length without cut off waste;

Shearing Machine Power: hydraulic

6.5 Elbow Machine for downspout pipe

This Elbow forming machine bend the roll-formed downspout pipes to a certain angle. It is composed of pressing machine and curving die.