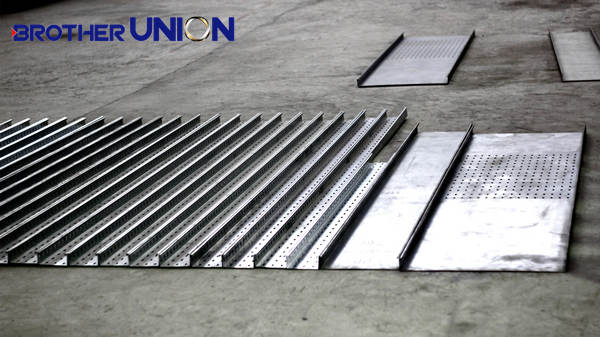

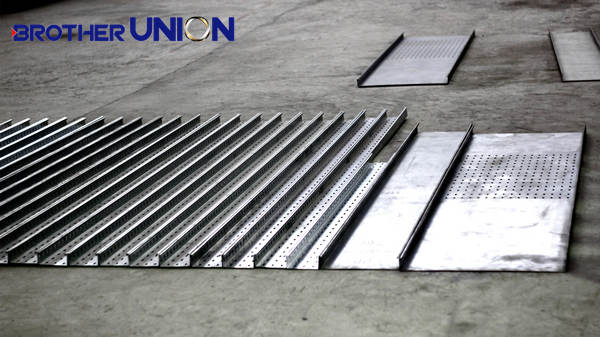

Roll Forming Machine for Cable Trays

The cable tray roll forming line produces cable trays from width 100mm to 600mm by adjusting the mobile side of the roll forming mill.

This cable tray machine has a hydraulic uncoiler, servo feeding, mechanical punching machine, pre-cut-off, gearbox driving roll forming mill, and product out conveyor.

The mechanical press punches the holes on the cable trays preciously, and a pre-shearing device cut the profile to length accurately for the next step - roll forming.

The duplex structure roll forming mill has two cantilevered mills facing each other. The width of the cable trays can be changed quickly by motor-adjusting one side of the duplex mill in or out. the design's maximum width is 600mm, and the minimum is 100mm. so the machine has the ability to produce a series of cable trays with bottom width from 100mm to 600mm.

Brother Union Machinery, as a professional roll forming machine and coil processing equipment manufacturer, we have been providing cable tray roll forming solutions with automatic roll forming line, semi-automatic line, cost-economical line.

Customized roll forming machines and related equipment are available. Just write us an email, we will send the proper proposal and price according to your requirements.

Video of Cable Tray Machine

Cable Tray Profile Drawing

Advantages of Brother Union Cable Tray Machine

Sturdy machine Base and Framing, longer service life.

Quality Roller Dies made of qualifed material

Automatic control system

Finished Cable Trays have accurate cut to length

Precise hole punching and accurate hole position

Free the operators' hand, save labours

Easy Installation, Easy Operation, and Easy Maintainance

High production efficiency

Cassette type roll forming for mutiple profiles of cable tray/ladder in one production line.

Cost-effective

Custom-made roll forming machines are available.